Sand Cast Bronze Plaques

Sand cast bronze plaques are a traditional material for memorials and

commemorative markers.

Sand cast bronze plaques are a traditional material for memorials and

commemorative markers.

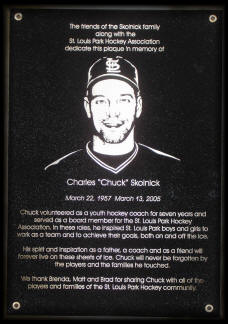

The plaque at left is 17" wide by 25" high. It weighs 55 lbs. The artwork

was adapted from a photograph by one of our artists. It's a stunning piece

of art in its final installation.

Plaques are typically between 3/8 to 7/16 inch thick. Because we use

computerized type setting, your plaque can be made using thousands of

different type faces limited only by the accuracy of the sand molding

process. You can incorporate two dimensional black and white art. In

addition, bas-relief busts and other sculptural artwork can be added to

plaques.

To calculate the estimated weight in pounds of your bronze plaque, figure

the area in square inches (length times width). Multiply the area times

0.1238. This is the weight in pounds.

Our bronze plaques are normally made in silicon bronze (UNS C87500)

unless you specify otherwise. Plaques can also be made in aluminum for

weight and cost savings.

Click here for an explanation of

how to order a

bronze plaque.

Key Benefits

- Bronze is beautiful. It is luxurious, luminous and lustrous. We use

the same grade of bronze that was the choice of Rodin, Degas, Picasso,

and many more of the world's greatest sculptors.

- These are substantial pieces that will speak through the ages.

- Bronze is corrosion resistant. Typical bronze plaques will last

thousands of years. Little maintenance is required if you allow it to

develop its natural patina.

- Sand cast bronze plaques are the traditional way of commemorating a

special person, an architectural edifice or an event.

- St. Paul Brass has over 125 years of experience making bronze

plaques. We can help you with every step of the process.

- Contact

us at 651-488-5567 for a free, fast quote.